Push-Through Reverse Print

EXCLUSIVE TIPS FOR PUSH-THROUGH REVERSE PRINT PROCESS

Looking for a great way to create an authentic distressed print?

Use a push-through print on our Triblend Jersey fabric.

1. DESIGN

It’s best to choose bold designs with dark colors. Lighter colors also work well, as long as they contrast with the triblend color.

2. THINK IN REVERSE

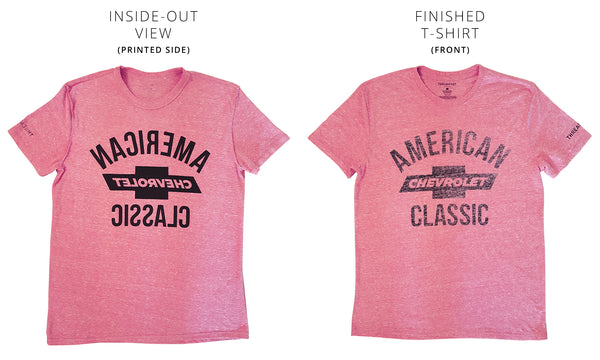

Be sure to flip or reflect your graphic on a vertical access prior to outputting separations. (See Chevy and NASA Inside-Out View for reference)

3. INK TYPE

Water-Base or Soft Plastisol will give the best results for a successful application. The low-viscosity characteristic of these inks allows for penetration through the fabric. Additionally, these inks will result in a very soft-hand finish (aka: little to no texture), which is most important as the print will be in contact with the wearer’s skin.

4. MESH SELECTION

A mesh with a high percentage of open-area (86-156 traditional or 135-180 thin-thread) will allow a higher volume of ink to saturate the fabric.

5. SQUEEGEE SELECTION AND SETTINGS

A triple-durometer squeegee with a rigid core and a soft edge (65/95/65) at a 5˚ angle is recommended. This allows for a high pressure squeegee pass with minimal flex which will drive the ink into the fabric.

6. END OF SEQUENCE FLASH

The necessity of printing through the fabric to achieve the “Push-Through” effect will result in wet ink residue on the printing platen. This is an issue as the wet ink residue can transfer and smear onto subsequent garments as they are loaded onto the printing platens. It is recommended that the print is flash-dried at the end of the print sequence just prior to offloading garments.

7. TEST

As always, be sure to do a test run to make sure the process worked properly.

Threadfast triblends are built with 38% cotton, giving a vintage, frosted face to the garments…the ideal construction to accomplish the reverse print process. This process works on all Threadfast triblend styles in light colors: 102A, 202A, 202B, 102C, 302G, 302Z.